How to Plan and Install Industrial Wiring

A Complete Guide for Beginners

Industrial wiring plays an important role in strengthening factories, workshops, and large-scale facilities. Unlike domestic wires, industrial electrical systems are more complex as they handle heavy machinery, high voltage and continuous operation. Planning and establishing industrial wiring is an essential skill for electricity, technicians and engineering students who want to create a professional career in this field. In this guide, we will run you through the major stages of planning and installing industrial wiring.

In this guide, we will walk you through the key steps of planning and installing industrial wiring.

1. Introduction to Industrial Wiring

Industrial wiring is the process of installing electrical circuits and systems in manufacturing plants, factories or large commercial places. This includes the correct cable, protective equipment, selecting distribution boards and ensuring safety compliance.

Key differences from domestic wiring:

• Handles high voltage and current.

• Strong insulation and large cable shapes are required.

• Advanced security systems (circuit breakers, relay, earthing) are included.

• Industrial safety codes and standards should be followed.

2. Planning the Wiring Layout

The proper plan ensures safety, efficiency and cost-effectiveness.

Steps in Plan:

Understand the requirement of electricity - calculate the total load of machines and equipment.

• Site Survey - Identify places for switchboard, machine, lighting and emergency systems.

• Choose a wiring system - Decide whether to use surface wiring, conduit wiring or cable tray.

• Create a wiring diagram-Use a single-line diagram and circuit layout for secrecy.

• Ensure compliance - follow local electric codes and industrial standards.

3. Tools and Materials Required

Before installation, prepare the right tools and materials.

• Tools: Wire stripper, pliers, tester, multimeter, drilling machine, conduit bender.

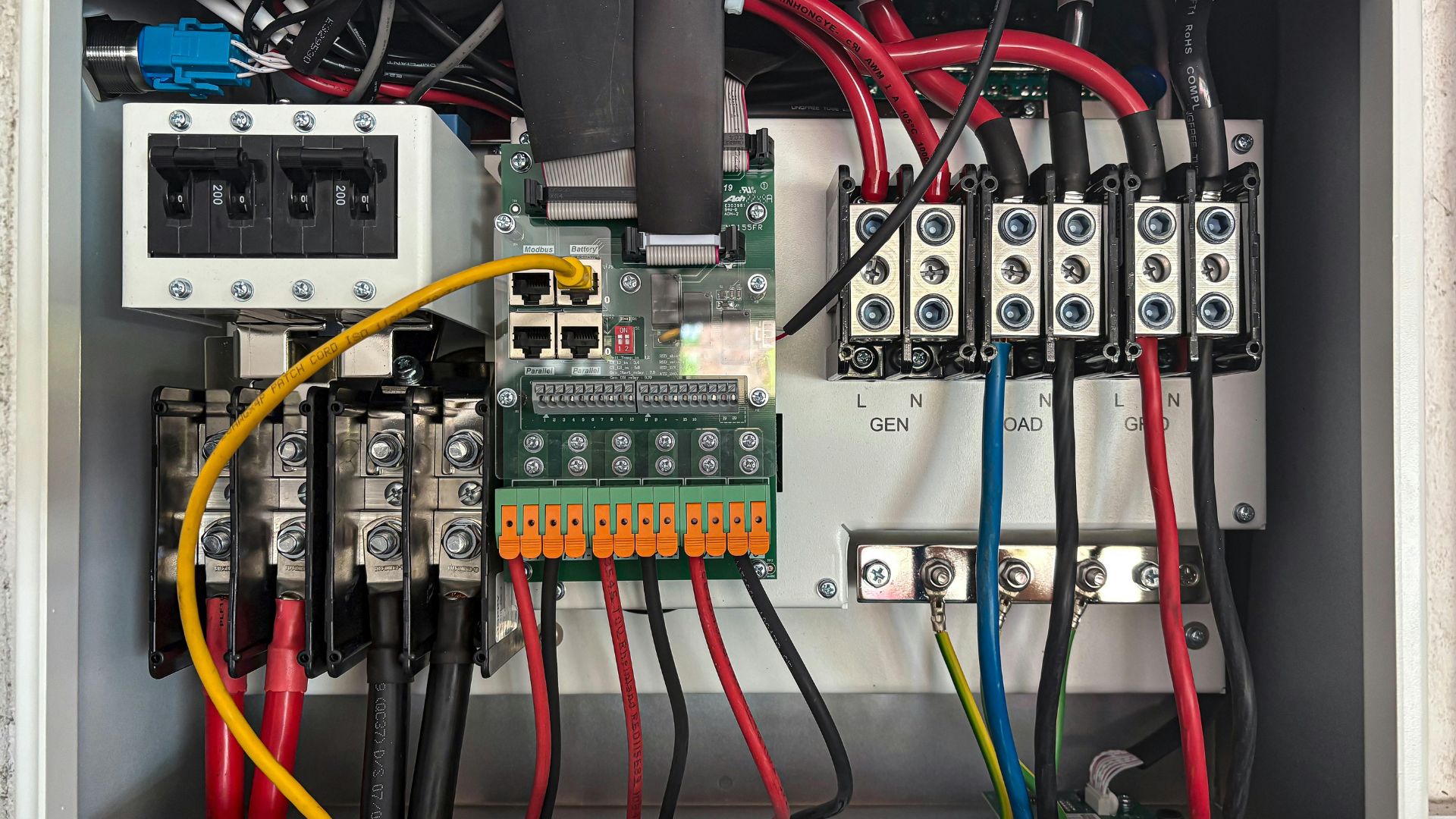

• Materials: Industrial cables, conduits, junction boxes, circuit breakers, distribution panels, switches, sockets, and earthing rods.

4. Installation Process Step-by-Step

Step 1: Marking and Layout

• Mark position for machines, switchboards and panels.

• Install a conduit or cable tray along the layout path.

Step 2: Wiring and Connections

• Pull the wires through the conduits/cable tray.

• Connect wires to switch, sockets and distribution boards.

• Label wire for identification.

Step 3: Earthing and Grounding

• Install proper earthing to avoid electric shock.

• Use copper plates, earthing rods, or chemical earthing systems.

Step 4: Installing Protective Devices

• Fix Circuit Breakers, MCB, MCCB and Fuses.

• Ensure proper ratings for each device according to load.

Step 5: Testing and Commissioning

• Check continuity, insulation resistance and polarity.

• Test with a multimeter before activating the system.

• Run trial operation to ensure smooth functioning.

5. Safety Precautions in Industrial Wiring

Safety should always be the priority.

• Never work on live wires.

• Always wear insulating gloves and safety gear.

• Use proper earthing to prevent electric shocks.

• Avoid overloading circuits.

• Follow government and industrial electrical codes.

6. Career opportunities in industrial wires

Learning industrial wiring opens many opportunities in Nepal and abroad.

• Jobs in factories and industries - as an electrician or technician.

• Construction Projects—Industrial Sites, Commercial Complex.

• Employment abroad - demand in Gulf countries, Malaysia and other areas.

• Entrepreneurship - starting your own electrical service business.

Final thoughts

Industrial wiring is not only about adding wires - it is about ensuring safe and reliable power distribution in large features. With proper training, equipment and safety measures, one can master the process of planning and installing industrial wiring.

If you are looking to make a career in the electric field, enrolling in a professional industrial wiring training program can help you get skills, certification and job opportunities in Nepal and abroad.

Recent Post

-

03 Feb 2025

03 Feb 2025How to Become a Plumber in Nepal

-

11 Aug 2025

11 Aug 2025Common Digital Marketing Mistakes to Avoid

-

12 Aug 2025

12 Aug 2025How to Become a Professional Video Editor

-

13 Aug 2025

13 Aug 2025The Impact of AI on the Future of Graphic Design

-

13 Aug 2025

13 Aug 2025How to Secure Your WordPress Site from Hackers

-

14 Aug 2025

14 Aug 2025Common AC Problems and How to Fix Them

-

14 Aug 2025

14 Aug 2025Career Opportunities in Motor Rewinding in Nepal

-

17 Aug 2025

17 Aug 2025Different Types of Welding and Their Uses

-

19 Aug 2025

19 Aug 2025Latest automobile technologies in 2025

-

19 Aug 2025

19 Aug 2025Top Tools Every Motorbike Mechanic Need